cattle working systems layout

Practical tips on why some handling systems work better than others. Equipment and supplies used at the squeeze chute and headgate.

Have A Free Look On One Man Or Two Man Corral Designs

Ackerman Distributing Livestock Agricultural Equipment 800-726-9091 970-284-5599 La Salle CO.

. Fig 7-2 Cattle handling layouts for up to about 75 head Fig 7-3 Small. Or equipment for at least getting cattle up to remove calves from the herd for sale. If youre getting few results try a more general search term.

SCOPE OF WORK DESIGN CONSTRUCTION SCHEDULE The following schedule identifies the estimated design and construction phases for this project and the estimated durations. Visit The Experts Now Save on All Your Tool Equipment Needs. Various positions as it closes.

Powder River Cattle Working Systems Alleys Tubs Complete Handling Facilities. They are always there for all of our needs on the ranch. Cattle can be easily worked in any order desired.

If you are planning to build new corrals or other cattle handling facilites you can download blueprints of cattle pen layouts that will reduce stress on cattle and improve handling efficiency. The circular crowding pens. Fort Collins Colorado 80523.

Ad Quality Tools For Serious Work. It takes advantage of the natural circling behaviour of cattle and sheep. The enterprise budget in Table 1 shows income and variable costs for the operation under these cir-cumstances on a per-head basis.

People who searched for System Engineer jobs in Hoboken NJ also searched for system admin network administrator desktop engineer deployment engineer sales engineer systems manager network engineer support engineer windows engineer linux engineer. The crowd pen must always be level. The primary purposes of cattle working facilities and equipment are to provide a fast and efficient way to handle and work cattle provide safe working.

Shop a wide selection of farm and livestock equipment. Now assume that this producer invests 5000 in a cattle handling facility that includes a headgate and holdingworking. Ad Residential and Commercial Fencing.

Family Owned Operated Since 1981. If the system includes a ramp it should be located within the single file chute. 7931 open jobs for Systems design engineer in New York.

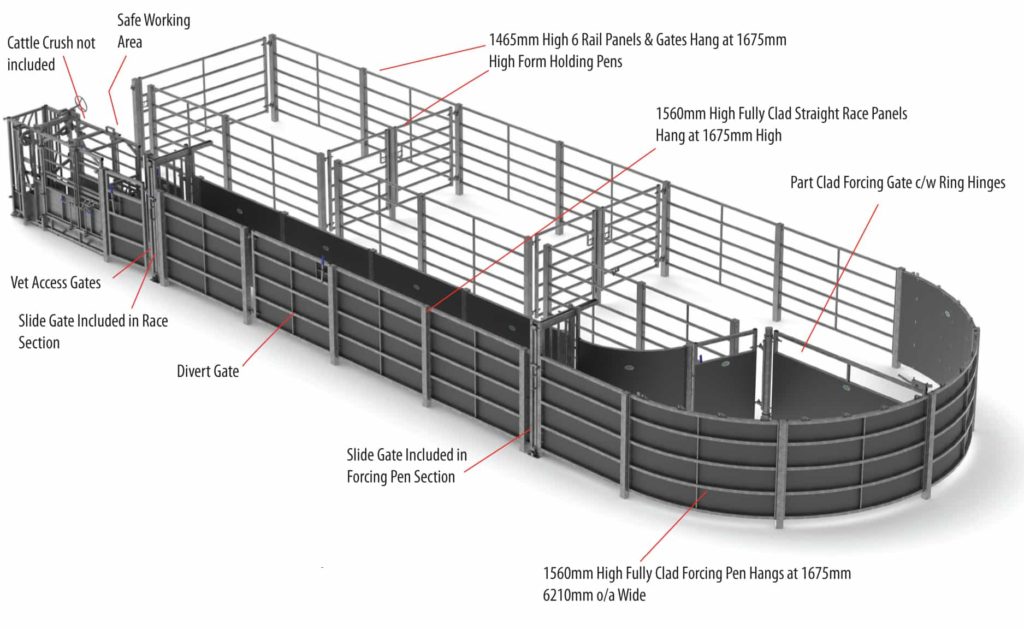

All of the layouts are set up so that cattle can be sorted and held in groups. Design Service Essential parts of the working facilities include 1 cattle pens 2 crowding pen 3 working alley 4 squeeze chute and headgate and 5 loading chute. Search Systems design engineer jobs in New York NY with company ratings salaries.

Design Development Phase 50 Minimum 42. Provide a refrigerator. Customizable Working Systems to Fit your Design.

We build to Please. Equip all gates with self-locking latches and provide a safety. Cattle Handling Systems and Layout of Cattle Corrals and Races.

Site Access Approvals Schedule Design Kick-off Meeting 14 2. Heaviest Powder River Tub Alley System. PROJECT PHASE ESTIMATED DURATION Calendar Days 1.

Solid fence and gate is most effective because the one escape route the cattle can see is through the working chute. He System 2000 is the most advanced cattle working system available. Sheeting is 68 Tall.

Handling Facility Layout Rules. Call Today for a Free Estimate. Some cattle handling systems work like well-oiled machines.

Tips For Creating Beef Cattle Handling Facilities

Tips For Creating Beef Cattle Handling Facilities

Sample Cattle Handling Systems

Resultado De Imagen Para Www Corraldesigns Com Cattle Cattle Barn Cattle Farming

Sample Cattle Handling Systems System Layout Design

Sample Cattle Handling Systems

Minimum Working Chute Inside Barn Cattle Ranching Cattle Farming Cattle Corrals

Sample Cattle Handling Systems

Page Not Found Ministry Of Food Agriculture And Rural Affairs